ME- 218-F STEAM & POWER GENERATION LAB

L T P Sessional : 25 Marks

- - 2 Exam : 25 Marks

Total : 50 Marks

Duration of exam : 3 Hrs.

List of Experiments:

1. To study low pressure boilers and their accessories and mountings.

2. To study high pressure boilers and their accessories and mountings.

3. To prepare heat balance sheet for given boiler.

4. To study the working of impulse and reaction steam turbines.

5. To find dryness fraction of steam by separating and throttling calorimeter.

6. To find power out put & efficiency of a steam turbine.

7. To find the condenser efficiencies.

8. To study and find volumetric efficiency of a reciprocating air compressor.

9. To study cooling tower and find its efficiency.

10. To find calorific value of a sample of fuel using Bomb calorimeter.

11. Calibration of Thermometers and pressure gauges.

Note:

1. At least ten experiments are to be performed in the semester.

2. At least eight experiments should be performed from the above list. Remaining two experiments may either be performed from the above list or designed & set by the concerned institute as per the scope of the syllabus.

Experiment No: 1

Aim: To study low pressure boilers and their accessories and mountings.

Apparatus: Models of low pressure boilers and their accessories and mountings.

Theory: A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.

Boiler properties:

(i)Safety: The boiler should be safe under operating conditions.

(ii) Accessibility: The various parts of the boiler should be accessible for repair and maintenance.

(iii) Capacity: Should be capable of supplying steam according to the requirements

(iv) Efficiency: Should be able to absorb a maximum amount of heat produced due to burning of fuel in the furnace.

(v) It should be simple in construction.

(vi) Its initial cost and maintenance cost should be low.

(vii) The boiler should have no joints exposed to flames.

(viii) Should be capable of quick starting and loading.

Boilers are classified mainly into two categories:

1. Fire tube or Low Pressure boilers

2. Water tube or High Pressure boilers.

Low pressure boilers are Vertical, Cochran, Lancashire , Cornish, Locomotives, etc.

In fire tube boiler, hot gases pass through the tubes and boiler feed water in the shell side is converted into steam. Fire tube boilers are generally used for relatively small steam capacities and low to medium steam pressures. As a guideline, fire tube boilers are competitive for steam rates up to 12,000 kg/hour and pressures up to 18 kg/cm2. Fire tube boilers are available for operation with oil, gas or solid fuels.

Vertical Boilers: The vertical boiler is a simple type which consists of a firebox at the bottom and a copper barrel with a smoke tube. It typically is used to drive stationary engines and boats. Firing is accomplished by alcohol or solid fuel pellets. More sophisticated versions of the vertical boiler contain many small tubes and are sometimes fired by coal or charcoal.

Cochran Boilers: It is one of the best types of vertical multi-tubular boiler, and has a number of horizontal fire tubes it also a Low Pressure Boiler.

Construction: Cochran boiler consists of a cylindrical shell with a dome shaped top where the space is provided for steam. The furnace is one piece construction and is seamless. Its crown has a hemispherical shape and thus provides maximum volume of space.

Working: The fuel is burnt on the grate and ash is collected and disposed of from ash pit. The gases of combustion produced by burning of fuel enter the combustion chamber through the flue tube and strike against fire brick lining which directs them to pass through number of horizontal tubes, being surrounded by water. After which the gases escape to the atmosphere through smoke box and chimney.

Specifications:

S 1. hell diameter 2.75 m

2.Height 5.79 m

3. Working pressure 6.5 bar (max. pressure = 15 bar)

4.Steam capacity 3500 kg/hr (max. capacity = 4000

5. Heating surface 120 m2

6.Efficiency 70 to 75% (depending on the fuel used)

Lancashire boilers: Lancashire is a stationary fire tube, internally fired, horizontal, natural circulation boiler. It is a commonly used in sugar – mills and textiles industries where along with the power steam and steam for the process work is also needed.

The specifications of Lancashire boiler are given below:

Diameter of the shell – 2 to 3 m.

Length of the shell – 7 to 9 m

Maximum working pressure – 16 bar

Steam capacity – 9000 kg/h

Efficiency – 50 to 70 %

Locomotives boilers: The Locomotive type boiler, shown in Figure 8, consists of a copper barrel and an outer and inner firebox attached to the rear of the barrel. Perfectly round pressure vessels carry pressure loads by developing hoop tension stresses in the wall of the boiler. In this case, there is no tendency for the walls to bend. If a pressure vessel is not perfectly round, the walls will bend because the walls will bend attempting to form a perfect circle as it pressurizes. The results in a combined stress field with high stress levels. Since the firebox is not circular, it is necessary to provide additional structural members to strengthen non circular surfaces. This is the reason for stay bolts and structural beams in the firebox assembly.

Thermal stresses also occur as a result of thermal expansion, therefore a boiler must be designed to carry both thermal and pressure loads. In a Belpaire type firebox, the outer wrapper and crown sheet may be stiffened by beams or girder stayed to each other. Both side plates of the outer firebox are cross stayed since they are flat. Flat surfaces on the back head and smoke box tube plate can be stiffened or stayed. Sometimes a combination of both is used resulting in a very strong boiler. If two or more stays are used, once can be hollow and used to route the blower line to the smoke box. Tubes extend from the front tube plate in the smoke box to the rear tube plate, which is located at the front of the fire box.

This type of boiler can be fired by coal if grates are installed. Liquid fuel burners can also be employed. The locomotive type boiler is the most difficult to build but is very efficient and allows the realism of a coal fire. It requires a suction fan and a blower, since it is a forced draft system. Its water capacity may be less than a comparable type C boiler. The water level must be carefully maintained so that the crown sheet is always covered, otherwise the boiler will be damaged.

Mountings of boiler: There are different fittings and device which are necessary for the operation and safety of a boiler. The various mountings used on the boiler:

1. Water level indicator

2. Pressure gauge

3. Safety valves

4. Fusible plug

5. Blow off cock

6. Feed check valve

7. Stop valve or Junction valve

Accessories of boiler: There are auxiliary plants required for steam boiler for their proper operation & for increase of their efficiency. The various accessories are:-

1. Feed pump

2. Economiser

3. Air pre-heater

4. Super heater.

5. Injector

Conclusion: Hence the study low pressure boilers and their accessories and mountings is completed.

Experiment No: 2

Aim: To study high pressure boilers and their accessories and mountings.

Apparatus: Models of high pressure boilers and their accessories and mountings.

Theory: Boiler is an apparatus to produce steam. Thermal energy released by combustion of fuel is used to make steam at the desired temperature and pressure. The steam produced is used for producing mechanical work by expanding it in steam engine or steam turbine, heating the residential and industrial buildings and performing certain processes in the sugar mills, chemical and textile industries.

Boilers are classified mainly into two categories:

<!--[if !supportLists]-->1. <!--[endif]-->Fire tube or Low Pressure boilers.

<!--[if !supportLists]-->2. <!--[endif]-->Water tube or High Pressure boilers.

High pressure boilers are Babcock and Wilcox, Sterling

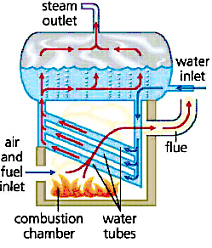

In water tube boiler, boiler feed water flows through the tubes and enters the boiler drum. The circulated water is heated by the combustion gases and converted into steam at the vapour space in the drum. These boilers are selected when the steam demand as well as steam pressure requirements are high as in the case of process cum power boiler / power boilers.

Most modern water boiler tube designs are within the capacity range 4,500 – 120,000 kg/hour of steam, at very high pressures.

Babcock and Wilcox boiler: Babcock and Wilcox is a water-tube boiler is an example of horizontal inclined tube boiler it also a High Pressure Boiler.

Construction: Babcock and Wilcox boiler with longitudinal drum. It consists of a drum connected to a series of front end and rear end header by short riser tubes. To these headers are connected a series of inclined water tubes of solid drawn mild steel. The angle of inclination of the water tubes to the horizontal is about 15° or more.

Working: The fire door the fuel is supplied to grate where it is burnt. The hot gases are forced to move upwards between the tubes by baffle plates provided. The water from the drum flows through the inclined tubes via down take header and goes back into the shell in the form of water and steam via uptake header. The steam gets collected in the steam space of the drum. The steam then enters through the antipriming pipe and flows in the superheater tubes where it is further heated and is finally taken out through the main stop valve and supplied to the Steam turbine or Steam engine when needed.

Sterling boiler: Stirling boilers are one of the larger arrangements for a water-tube boiler: acceptable for stationary use, but impractical for mobile use, except for large ships with modest power requirements. They consist of a large brick-built chamber with a sinuous gas path through it, passing over near-vertical water-tubes that zig-zag between multiple steam drums and water drums. Example of water tube boiler where bent tube are used instead of straight tube which are used in Babcock and Wilcox boiler.

They are amongst the older, "large-tube" designs of water-tube boilers, having water-tubes that are around 3¼ inches (83 mm) in diameter. The tubes are arranged in near-vertical banks between a number of cylindrical, horizontal steam drums (above) and water drums (below). The number of drums varies, and the Stirling designs are categorized into 3-, 4- and 5-drum boilers. The number of tube banks is one less than this, i.e. 2, 3 or 4 banks.

Gas flow from the furnace passes through each bank in turn. Partial baffles of firebrick tiles are laid on each bank, so as to force the gasses to flow first up, and then down through each bank. Unusually, much of the gas flow is along the tubes' axis, rather than across them.

All circulation, both up and down, is through the heating tubes and there are no separate external downcomers. The steam drums and, (in a 5-drum boiler) the water drums, are however linked by short horizontal pipes and these form part of the circulation circuit.

The tubes themselves are seamless-drawn steel and mostly straight, with gently curved ends.[3] The setting of the boiler is a large brick-built enclosure, but the steam drums are suspended from a separate girder framework inside this, so as to allow for expansion with heat. The tubes, and the water drums in turn, are hung from the steam drums, again to allow free expansion without straining the tube ends. Owing to their curved ends the water-tubes may enter the drums radially, allowing easy sealing, but this was also a feature considered, according to the fashion of the time, to be important on account of expansion.

Lamont boiler:-

It is a high pressure boiler. It is water tube boiler working on forced circulation system. The water from the storage drum is drawn by the circulation pump. Compressed to about 2.5 bar above the drum pressure and supply to header which distribute water to the generating tube G. Here some water is converted into steam and a mixture of water and steam then pass into the storage drum.. The steam is further heated in the super heater before being taken out water from hot well is supplied by the feed pump through the economiser to the storage drum. The sludge if any would settle drum and can be removed from the bottom.

Loeffler boiler:- Loeffler boiler is also a high pressure water tube boiler employs the advantage of forced circulation and indirect heating. It use steam as heat carrying and heat absorbing medium before the furnace heat is only supply to economiser and super heater. The feed water from the feed pump is fed to the drum through the economiser where it gains heat from out going gases.

Mounting of high pressure boiler: There are different fittings and device which are necessary for the operation and safety of a boiler. The various mountings used on the boiler

1. Water level indicators: The function of a water level indicator is to indicate the level of water in the level constantly. It is also called water gauge.

2. Fusible plug: The function of a fusible plug is to prevent the boiler against damage due to overheating for low water level.

3. Steam stop valve: A junction valve is a valve which is placed directly over a boiler and connected to a steam pipe which carries steam to the engine. If a valve is placed in the steam pipe leading steam to the engine and placed near the engine. It usually termed as stop valve. The larger sizes are called Junction valve and smaller sizes Stop valve.

4. Feed check valve: The function of a feed check valve is to control the supply of water to the boiler and to prevent the exception of water from the boiler when the pump pressure is less as pump is stopped.

5. Blow off cock: A blow off cock or valve performs the two functions. They are it may discharge a portion of water when the boiler is in operation to blow out mud scale or sediments periodically and It may empty the boiler when necessary for cleaning, inspection and repair.

6. Safety valve: The function of a safety valve is to release the excess steam when the pressure of steam inside the boiler exceeds the rated pressure. The various type of safety valve are Dead weight safety valve, Spring loaded safety valve and High steam & low water safety valve.

7. Pressure gauge: The function of a pressure gauge is to measure the pressure exerted inside the vessels. It is usually constructed to indicate upto double the maximum working pressure. Its dial is graduated to read pressure in kgf/cm2 gauge. There are two type of pressure gauges, they are Bourdon tube type pressure gauge and Diaphragm tube type pressure gauge

8. Man and mud holes

Accessories of high pressure boiler: There are auxiliary plants required for steam boiler for their proper operation & for increase of their efficiency. The various accessories are

1. Feed pump: The feed pump is a pump which is used to deliver feed water to the boiler . It is desirable that the quantity of water supplied should be at least equal to that evaporated and supplied to the engine. Two type of pumps which are commonly used as feed pump are Reciprocating pump and Rotary pump.

2. Injector: The function of an injector is to feed water in to the boiler. It is commonly employed for vertical and locomotive boiler and does not find its applications in large capacity high pressure boiler.

3. Evaporator: Evaporator is used in high pressure boiler which is placed after the air in the way of flue gases water are tube. Hence evaporator is a unit which consumes the energy of flue gases in boiler. Its main function is to convert the water to steam add much to the boiler efficiency.

4. Economiser: An economiser is a device in which the waste heat of the flue gases is utilized for heating the feed water. Economiser is very important part of the boiler, with the help the economiser the efficiency of the boiler increased and the evaporative capacity of the boiler is increased. Economiser are of two type Independent type and Integral type.

5. Super heater: The function of a super heater is to increase the temperature of the steam above its saturation point.

6. Air-pre heater: The function of air preheatere is to increase the temperature of air before is enters the furnace. It is generally placed after the economiser. So that flue gases pass through the economiser and then to air preheat. Usually, there are three types of pre-heater are Tubular type, Plate type and Regenerative type.

Conclusion: Hence the study high pressure boilers and their accessories and mountings is completed.

Experiment No: 3

Aim: To prepare heat balance sheet for given boiler.

Theory: The boiler circulation are generally based upon the high calorific value of 1 kg of fuel considered as 100 %.

Heat losses in the boiler:- The efficiency of boiler is never 100 % as only a portion of heat supplied by the fuel is utilized rest of it is lost:-

1. Heat carried away by dry product of combustion.

2. Heat carried away by the steam product by the combustion of hydrogen present in fuel.

3. Heat carried away by moisture in fuel and air.

4. Heat loss due to incomplete combustion of carbon to carbon monoxide instead of carbon dioxide and thus escape of combustable matter in the flue gases and ash.

5. Heat loss due to radiation.

Method of minimizing the heat loss:-

1. The heat loss to chimney gases may be minimized by installing an economiser in between the boiler and chimney.

2. Loss of heat may be minimized by providing the boiler with an effective draught system which will ensure sufficient supply of air through the fuel in furnace.

3. Heat loss due to unburnt fuel which may fall into ash pit may be minimized by properly sizing of coal.

4. Heat loss due to moisture content in the fuel may be minimized by making the fuel dry before charging into the boiler furnace.

5. Heat loss due to external radiation may be minimized by providing effective covering of insulating material on the boiler parts which are liable to radiate heat.

Procedure:

The heat balanced sheet of a boiler:

1. Heat utilized by generation of steam:- Useful heat absorbed, H1 = m (h1-h2)

H1 = Equivalent evaporation. 2256.9 KJ

2. Loss due to moisture in fuel:-

The moisture in the fuel is evaporated and superheated and thus the heat is lost.

Loss due to moisture in fuel, H2 =m1 (n11-n21)

Where m1 = Mass of moisture per kg of fuel of fired

n11 = Enthalpy of steam formed

n21 = Enthalpy of liquid at temperature of boiler furnace.

3. Loss due to H2O vapour from combustion of Hydrogen:-

This is found similarly to loss due to moisture in fuel.

4. Loss due to moisture in air:-

This is also found in the similar way as above and it is generally negligible.

5. Loss due to dry flue gases:-

This is the target loss that takes place inside the boiler. This is given by :-

H3 = m2Cp (tg-ta)

Where m2= Mass of dry flue gases per kg of fuel.

Cp= Specific heat of dry flue gases

tg = Temperature of flue gases

ta = Temperature of atmospheric (gases) air

6. Loss due to incomplete combustion of carbon:-

This loss is caused by incomplete combustion of carbon to carbon monoxide instead of carbon dioxide.

H4 = m3.CV of CO

H4 = CO.C/(CO2+CO. CV of CO)

C = Mass of carbon actually burned per kg of fuel

CO & CO2 % by volume

CV = Number of heat unit generated by burning 1kg of carbon contained in CO to

CO2 = 23820 KJ/ Kg

7. Loss due to unconsumed combustion to refuse:-

This loss is due to some unburnt carbon falling into the ash pit.

H5 = m4 .CV

m4 = Unburnt mass of carbon in refuse per Kg of fuel

CV = Calorific fuel of carbon.

Ex: HEAT BALANCE SHEET (Basis 1 Kg of low grade fuel)

Heat supplied

(K J)

|

% age

|

Heat Expenditure (K J)

|

% age

(in approx.)

|

Gross heat

supplied

|

100

|

(a) Heat utilized in steam generation

(b) Heat carried away by flue gases

(c) Heat utilized in evaporating and superheating the moisture fuel and water vapour formed

due

to burning of hydrogen of fuel.

(d) Heat loss by incomplete combustion

(e) Heat carried away by excess air

(f) Heat carried away by carbon nash

(g) Heat uncounted for such as radiation and error etc.

|

78.00

12.00

4.750

3.00

1.500

0.500

0.250

|

Total

|

100

|

Total

|

100

|

Conclusion: Hence preparation of heat balance sheet for given boiler.

Experiment No: 4

Aim: To Study the working of Impulse and Reaction steam turbines.

Apparatus: Model of Impulse and Reaction steam turbines.

Theory:

Steam turbines: The steam turbine is a prime mover in which the potential energy of steam is transformed into kinetic energy and latter in its turn is transformed into the mechanical energy of the rotation of the turbine shaft.

Classification of steam turbine: With respect to the action of steam, turbines are classified as:

• Impulse turbine

• Reaction turbine

1. Impulse turbine:- It is a turbine, which runs by the impulse of steam jet. In this turbine, the steam is first made to flow through a nozzle. Then the steam jet impinges on the turbine blades with are curved like bucket and are mounted on the circumference of the wheel. The steam jet after impinges glide over the concave surface of blades and finally leave the turbine. The top portion of Impulse turbine exhibits a longitudinal section through the upper half, the middle portion shows one set of nozzle which is followed by a ring of moving blades, while lower part indicate changes in press and velocity during the flow of steam through the turbine. The principle equation of this turbine is the well known “De level” turbine.

2. Reaction turbine:- In a Reaction turbine, the steam enters the wheel under pressure and flow over the blades. The steam while gliding proper the blades and then makes them to move. The turbine runner is rotated by the reactive forces of steam jets. In this, there is a gradual pressure drop takes place continuously over the fixed and moving blades. The fuel of fixed blades is that they after allow it expand to a larger velocity as the steam passes over the moving blades. Its K.E. is absorbed by them a three stage Reaction turbine.

Compounding: - If the steam is expended from the boiler pressure in one stage the speed of rotor becomes tremendously high which drop up practical complicacies. The are several methods of reducing this speed to lower value, all these methods utilized a multiple system of rotor in series. Keyed on a common shaft and the steam pressure or jet velocity is absorbed in stage as the steam flows over the blades. This is known as compounding:-

1. Velocity compounding:- Steam is expanded through a stationary nozzle from the boiler or inlet pressure to condenser pressure. So the pressure in the nozzle drops, the K. E. of steam increase due to increase in velocity. A portion of this available energy is absorbed by a row of moving blades. The steam then flow through the second row of the blades which are fixed. They redirect the steam flow without altering its velocity to the following nearest row moving blades. Where again work is done on them and steam with a low velocity from the turbine.

2. Pressure compounding:- In this rings of fixed nozzle incorporated between ring of moving blades. The steam of boiler pressure enters the first set of nozzle and expands partially. The K.E. of steam thus obtained in absorbed by the moving blades. The steam then expands partially in the second set of nozzles whose its pressure again falls and the velocity increases. The K.E. thus obtained is observed by the second ring of moving blades. This is repeated in stage 3 and steam finally leaves the turbine at low velocity and pressure.

3. Pressure- Velocity compounding:- This method is the combination of velocity and pressure compounding. The total drop in steam pressure is divided into stages and velocity obtained in each stage is also compounded. The ring of nozzle, are fired at beginning of each stage and pressure remains constant during each stage.

Conclusion: Thus the study is completed for the working of Impulse and Reaction steam turbines.

Experiment No: 5

Aim: To find dryness fraction of steam by separating and throttling calorimeter.

Apparatus: Ward steam bench

a) Steam boiler plant

b) Separating and throttling calorimeter

c) Measuring

d) Beaker

Theory: The separating calorimeter is a vessel used initially to separate some of the moisture from the steam, to ensure superheat conditions after throttling. The steam is made to change direction suddenly; the moisture droplets, being heavier than the vapor, drop out of suspension and are collected at the bottom of the vessel.

The throttling calorimeter is a vessel with a needle valve fitted on the inlet side. The steam is throttled through the needle valve and exhausted to the condenser. Suppose M kg of wet steam with a dryness fraction of x (state A) enters the separating calorimeter. The vapor part will have a mass of xM kg and the liquid part will have a mass of (1-x)M kg. In the separating calorimeter part of the liquid, say M1 kg will be separated from the wet steam. Hence the dryness fraction of the wet steam will increase to x1 (state B) which will pass through the throttling process valve. After the throttling process the steam in the throttling calorimeter will be in superheated state (state C).

Figure. T-S diagram of the separating and throttling calorimeter.

From the steady flow energy equation;

Q – W = hC - hB

Since throttling takes place over a very small distance, the heat transfer is negligible, i.e., Q = 0. Then the steady flow energy equation for the throttling process becomes,

hC = hB

Hence, enthalpy after throttling = enthalpy before throttling

hC = hf1 + x1 hfg1

If the pressure of the steam before throttling, the pressure and temperature of the steam after throttling, are known the value of x1 can be calculated using steam tables.

Dryness Fraction = Mass of dry steam

Mass of mixture

Therefore, X = (x1 * M2)/(M1 + M2) <!--[if !vml]--><!--[endif]-->

Where, M2 is the mass of condensate.

Steam generator separating & throttling calorimeter:

In separating & throttling calorimeter are used. The steam passing from a calorimeter may be steam containing some water particle in it. This method is basically for a wet steam. In this case it is necessary to dry the steam partially before throttling. This is done by passing the steam sample from the main through a operating calorimeter.

In separating calorimeter the steam is made to change its direction suddenly & water as heavy then steam separate out there due to inertia. The quantity of water separate out is measured, then the steam is passed through the throttling calorimeter. After that steam from calorimeter is collected and condensed & measure the condensate

X2=(h3-h2)/hfg2

Procedure:

- Start the boiler and supply steam to the separating and throttling calorimeter unit.

- Start the cooling water flow through the condenser.

- Open steam valve and allow the steam to flow through the calorimeters to warm through the steam.

- Open the throttle valve and adjust to give a pressure at exhaust of about 5cm Hg measured on the manometer.

- Drain the separating calorimeter.

- Start the test and take readings at 2-3 minutes intervals.

- When a reasonable quantity of condensate is collected measure the quantity of separated water and the quantity of condensate.

Observations & Calculations:

Using the average values, obtain the specific enthalpy of steam at (state C) hence calculate the dryness fraction of incoming steam. Also calculate the specific enthalpy of incoming steam.

1

|

2

|

3

|

4

|

5

|

6

|

Ave.

| |

Steam pressure in main P1 (bars)

| |||||||

Steam pressure after throttling P2 (bars)

| |||||||

Temperature of main T1 (oC)

| |||||||

Temperature after throttling T2 (oC)

| |||||||

Quantity of Separated water M1 (kg)

| |||||||

Quantity of condensate M2 (Kg)

| |||||||

Conclusion: Hence the dryness fraction of steam is______.

Experiment No: 6

Aim: To find power out put & efficiency of a steam turbine.

Theory: A steam turbine is a device that takes hot, high-pressure steam and extracts mechanical energy from it. This energy can then be used to do useful work that uses steam turbines is the steam power plant, which generates electricity used in everyday life.

An energy balance on the steam turbine tells us the relationship between the power output and the inlet and outlet states of the steam. A turbine is analyzed as an adiabatic (i.e., no heat transfer) device. The power output is then calculated as the mass flow rate of the steam multiplied by the difference in enthalpy between the inlet and outlet, or:

Conclusion: Hence the power output and efficiency of steam turbine are ________ and ________.

Experiment No: 7

Aim: To find the condenser efficiencies.

Theory: Steam condenser is a closed space into which steam exits the turbine and is forced to give up its latent heat of vaporization. It is a necessary component of a steam power plant because of two reasons. It converts dead steam into live feed water. It lowers the cost of supply of cleaning and treating of working fluid. It is far easier to pump a liquid than a steam. It increases the efficiency of the cycle by allowing the plant to operate on largest possible temperature difference between source and sink. The steam’s latent heat of condensation is passed to the water flowing through the tubes of condenser. After steam condenses, the saturated water continues to transfer heat to cooling water as it falls to the bottom of the condenser called, hot well. This is called sub cooling and certain amount is desirable. The difference between saturation temperature corresponding to condenser vacuum and temperature of condensate in hot well is called condensate depression.

There are two primary types of condensers that can be used in a power plant; they are direct contact or jet condenser and surface condenser.

Direct contact condensers condense the turbine exhaust steam by mixing it directly with cooling water. The older type Barometric and Jet-Type condensers operate on similar principles. In a jet condenser, steam escapes with cooling water and this mixture inhabits recovery of condensate to be reused as boiler feed water. In this case, the cooling water should be fresh and free from harmful impurities. However, with moderate size turbine units the jet condensers can be used if enough supply of good quality cooling water is available. Steam surface condensers are the most commonly used condensers in modern power plants. The exhaust steam from the turbine flows in the shell (under vacuum) of the condenser, while the circulating water flows in the tubes. The source of the circulating water can be a river, lake, pond, ocean or cooling tower.

The main function of a condenser is to only remove the latent heat of vaporization so that the temperature of condensate becomes equal to the saturation temperature of steam corresponding to the condenser pressure. It further theoretically elaborates complete absence of under cooling of condensate. Therefore, the maximum temperature to which cooling water can be raised is the condensate temperature at the minimum possible condenser pressure where only latent heat of vaporization is extracted without any under cooling. The condenser efficiency is given as the ratio of actual rise in the temperature of outlet cooling water to the maximum possible temperature rise in a saturated temperature at condenser pressure corresponding to the inlet cooling water temperature.

Mathematically,

Condenser efficiency = (Actual rise in the cooling water temperature)/{[Saturation temperature at condenser pressure] – [inlet cooling water temperature]}

Condenser efficiency = (T2 – T1)/(T3 – T1).

T1 and T2 are inlet and outlet cooling water temperature, and T3 is saturation temperature at condenser pressure.

Conclusion: Hence the condenser efficiency is _________.

Experiment No: 8

Aim: To study and find volumetric efficiency of a reciprocating air compressor.

Apparatus: (This is under observation) Two Stage Air Compressor Test Rig consists of a double stage reciprocating type air compressor driven by 2 HP Motor through a belt. The outlet of the air compressor is connected to reservoir (Tank) and suction is connected to another air tank with a calibrated orifice plate and a water manometer. Bellow is fitted on one side of the air tank to regulate the flow. Temperature of inlet air, after single compression, inlet and outlet of second compression and pressure in reservoir and at intermediate stage can be measured by thermometers and gauges. UTILITIES REQUIRED: Electricity 3 kW, 220V AC, Single Phase, Floor Area 1.5 x 0.75 m, Tachometer. TECHNICAL DETAILS: Compressor Double Stage, Double Cylinder Capacity 9 CFM max. Working Pressure 15 kg/cm2 max. Make Toyo/Sony/ELGI / standard available Drive 2 HP Spring Balance Dial type. Manifold Tank Suitable capacity. Flow Measurement Orificemeter with Manometer Temperature Sensors RTD PT :100 type Air Tank Capacity 145 liters with safety valve, shut off valve Pressure Gauge Bourdon type Control Panel Energy measurement Energy meter, MCB For over load protection, Digital Temp. Indicator : 0-199.9C, with multi-channel switch, On/off switch, Mains Indicator etc.

Theory:

Reciprocating compressors are often used with air reservoirs to provide compressed air for industrial and civil duties driving air tools etc.

The figure below shows a hypothetical indicator diagram for a single stage -single acting reciprocating compressor.

a ->1... Air is drawn into the cylinder on the suction stroke

1 ->2... The suction valve is closed and air is compressed according to the law Pvn = c

2 ->b... The delivery valve opens and air is delivered under pressure

b ->a... The delivery valve closes and the suction valve opens

1 ->2... The suction valve is closed and air is compressed according to the law Pvn = c

2 ->b... The delivery valve opens and air is delivered under pressure

b ->a... The delivery valve closes and the suction valve opens

Clearance Volume effect

<!--[if !supportLineBreakNewLine]-->

<!--[endif]-->

<!--[if !supportLineBreakNewLine]-->

<!--[endif]-->

A practical single stage compressor cylinder will have a small clearance at the end of the stroke. This clearance will have a significant effect on the work done per cycle.

In operation the air in the clearance volume expands to 5 before any fresh air is drawn into the cylinder. The stroke is from 1 to 2 with a swept volume of (V2 - V1 ) but the suction is only from 5 to 2 giving a volume of (V2 - V5 ) taken into the cylinder on each stroke.

In operation the air in the clearance volume expands to 5 before any fresh air is drawn into the cylinder. The stroke is from 1 to 2 with a swept volume of (V2 - V1 ) but the suction is only from 5 to 2 giving a volume of (V2 - V5 ) taken into the cylinder on each stroke.

1. Take the initial readings as required like cylinder diameter, pressures, volumes, etc.

2. Now, run the compressor to required time and note the relevant readings.

3. Calculate volumetric efficiency as per the observations and formulas as above.

Observations & Calculations:

Fill the following table as per specifications of the reciprocating air compressor:

HP

|

RPM

|

Tank Dimensions (L,B,H)

|

Max Pressure

|

No of cylinders

|

Fill the following table as per practical, theory and assumptions:

P1

|

P2

|

P3

|

P4

|

P5

|

V1

|

V2

|

V3

|

V4

|

V5

|

r

|

n

|

c

|

Volumetric Efficiency

|

Conclusion: Hence the volumetric efficiency of the reciprocating air compressor is ___________.

Experiment No: 9

Aim: To study cooling tower and find its efficiency.

Apparatus: Cooling Tower set up.

Theory: Cooled water is needed for, for example, air conditioners, manufacturing processes or power generation. A cooling tower is equipment used to reduce the temperature of a water stream by extracting heat from water and emitting it to the atmosphere. Cooling towers make use of evaporation whereby some of the water is evaporated into a moving air stream and subsequently discharged into the atmosphere. As a result, the remainder of the water is cooled down significantly. Cooling towers are able to lower the water temperatures more than devices that use only air to reject heat, like the radiator in a car, and are therefore more cost-effective and energy efficient.

Cooling towers use the evaporative cooling principle to cool the circulated water, and they can achieve water temperatures below the dry bulb temperature - tdb - of the air cooling air and they are in general smaller and cheaper for the same cooling loads than other cooling systems.

Cooling towers are rated in terms of approach and range, where

<!--[if !supportLists]-->· <!--[endif]-->the approach is the difference in temperature between the cooled-water temperature and the entering-air wet bulb - twb -temperature

<!--[if !supportLists]-->· <!--[endif]-->the range is the temperature difference between the water inlet and exit states

Since a cooling tower is based on evaporative cooling the maximum cooling tower efficiency is limited by the wet bulb temperature -twb - of the cooling air.

The water consumption - the make up water - of a cooling tower is about 0.2-0.3 liter per minute and ton of refrigeration. Compared with the use and waste of city water the water consumption can be reduced with about 90 - 95%.There are two main types of cooling towers

1. Natural draught

2. Artificial draught (Mechanical type)

(i) Forced draught (Forced fan)

(ii) Induced draught (Suction fan)

1. Natural draught:- When the circulation of air through the tower is by natural convection, it is known as a natural draught. In this, hot water from the condenser is pumped to top of tower where it is sprayed down through a series of spray nozzles. The hot water after giving its heat to air which circulates through the tower due to natural convection, gets cooled and is collected from bottom of tower.

2. Artificial draught: - When the circulation of air through the tower is by artificial convection i. e. Forced fan, Suction fan is known as artificial draught. It is of two type:-

(i) Forced draught: - The tower is completely encased with discharged opening at the top and fan at the bottom to produce flow of air.

(ii) Induced draught: - Here fan is placed at the top which draws air through the tower. The warm water to be cooled introduce at the top of the tower through spray nozzles. It falls through a series of trays which are arranged to keep the falling water to be broken up into fins drops. The cooled water is collected at the bottom.

Procedure:

1. Make the initial setting as per equipment.

2. Start the experiment and take the temperature readings.

3. Complete the calculations.

Observations & Calculations:

Ti

|

To

|

Twb

|

μ

|

Cooling Tower Efficiency

The cooling tower efficiency can be expressed asμ = (ti - to) 100 / (ti - twb)

where

μ = cooling tower efficiency - common range between 70 - 75%

ti = inlet temperature of water to the tower (oC, oF)

to = outlet temperature of water from the tower (oC, oF)

twb = wet bulb temperature of air (oC, oF)

The temperature difference between inlet and outlet water (ti - to) is normally in the range 10 - 15 oF.

Conclusion: Hence the efficiency of the cooling tower is _________.

Nice to be visiting your blog again, it has been months for me. Well this article that i’ve been waited for so long. I need this article to complete my assignment in the college, and it has same topic with your article. Thanks, great share. water damage repair

ReplyDelete